Inside Smart Industrial Parks: Integrating IoT for Advanced Manufacturing

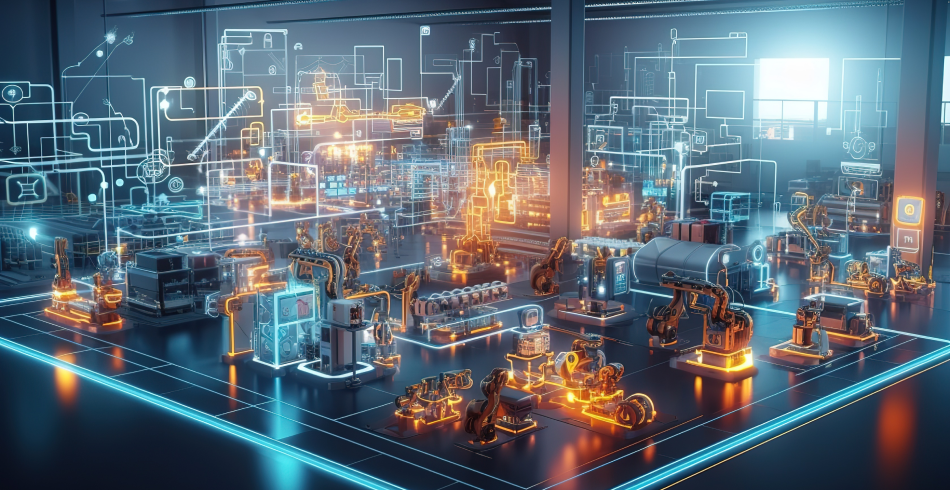

Since its inception, Internet of Things (IoT) has been reshaping traditional manufacturing methods and introducing a new age of industrial operations which are rooted in connectivity, intelligence, and unsurpassed efficiency. And as smart industrial parks continue to evolve and grow innovative each year, IoT remains a hot topic of conversation because of the pivotal role it plays in making smart and advanced manufacturing operations possible.

The IoT Revolution in Manufacturing

IoT is about fundamentally transforming manufacturing processes and raising the bar for efficiency, productivity, and sustainability. By using a sophisticated network of sensors, devices, and data analytics tools, IoT gives businesses the capabilities of real-time monitoring, predictive maintenance, and automated decision-making, leading to a more agile and responsive manufacturing ecosystem. In this article, we are going to take a closer look at the specific benefits that factories in smart industrial parks stand to get upon integrating this technology.

Benefits of IoT for Manufacturers in Smart Industrial Parks

1. Increased Efficiency and Productivity

As mentioned, IoT empowers real-time monitoring of equipment and processes, enabling proactive issue identification and operation optimisation. By enabling automation and streamlining manufacturing processes, IoT technologies reduce manual intervention, enhance operational efficiency and boost productivity levels. This type of automation ensures swift responses to market demands, minimising downtime, and maximising overall supply chain productivity.

For example: In a manufacturing plant equipped with sophisticated IoT systems, including advanced sensors installed throughout the facility, it is possible to collect real-time data on various aspects of production such as machine performance, temperature, humidity, and energy usage. This data is then analysed using sophisticated data analytics algorithms to identify patterns, anomalies, and opportunities for optimisation.

2. Enhanced Quality Control

With IoT, manufacturers leverage data-driven insights to streamline workflows and make informed decisions. Predictive analytics anticipate demand fluctuations, optimising production, and minimising bottlenecks. Additionally, real-time monitoring helps maintain high-quality standards by proactively addressing potential issues.

For example: With more sophisticated systems, the IoT sensors can continuously monitor the condition of machinery and equipment. Using predictive analytics, the system can detect early signs of potential equipment failures or malfunctions based on deviations from normal operating parameters. This enables the maintenance team to proactively schedule repairs or replacement parts before a breakdown occurs, minimising unplanned downtime and optimising overall equipment effectiveness.

3. Supply Chain Optimisation and Agility

Leveraging IoT in supply chain management provides unprecedented visibility and control. IoT enables real-time tracking of materials, optimises inventory levels, and predicts equipment maintenance needs, enhancing supply chain efficiency and reliability. Moreover, businesses in smart industrial parks equipped with IoT capabilities can swiftly adapt to changing market conditions and customer demands. Data-driven insights facilitate agile decision-making, enabling manufacturers to seize opportunities and mitigate risks promptly.

For example: If demand for a particular product suddenly increases, the IoT-enabled production line can automatically reconfigure itself to prioritise the production of that item. This flexibility allows manufacturers to quickly adapt to market fluctuations and customer demands, enhancing their agility and responsiveness.

4. Energy Management and Sustainability

With IoT, manufacturers in smart industrial parks can effectively manage energy usage in real time, reducing operational costs and reducing the carbon footprint of their supply chain activities. IoT also enables the implementation of sustainable practices by facilitating better resource management and energy efficiency.

For instance, sensors can monitor energy usage in real time, identifying areas for optimisation and waste reduction.

Challenges and Solutions

Integrating IoT technologies into industrial parks faces several challenges, primarily centred around ensuring data security and interoperability among different systems. Data security concerns arise due to the sensitive nature of the information collected and transmitted by IoT devices. Interoperability issues stem from the need to connect and communicate effectively between various IoT devices, sensors, and existing infrastructure.

To address these challenges, robust security protocols must be implemented to safeguard data integrity and privacy. This involves encryption, authentication mechanisms, and secure communication protocols to prevent unauthorised access and data breaches. Additionally, systems need to be flexible enough to seamlessly integrate with diverse existing infrastructure, such as legacy systems and equipment, without disrupting operations.

Furthermore, adhering to industry standards and best practices is essential to ensure compatibility and interoperability across different IoT devices and systems. This may involve adopting standardised communication protocols and interfaces to facilitate smooth data exchange and collaboration between disparate systems.

The Future of Smart Industrial Parks

The future of smart industrial parks is poised for remarkable growth, fuelled by the continuous evolution of IoT technology. With ongoing innovations in sensors, data analytics, and AI-driven automation, these parks are sure to see more transformations going forward, promising unseen levels of efficiency and productivity in the years to come exhibiting fully integrated, autonomous operations and more. Embracing IoT is no longer just an option but a necessity for manufacturers seeking to thrive in an ever-changing global market. By staying ahead of the curve and embracing these advancements, manufacturers can ensure their enduring relevance and success in the dynamic landscape of manufacturing.