Role of Ergonomic Design in Warehousing

With people at the heart of the logistics and warehousing ecosystem, here is how to design a Grade A warehouse for them.

It goes without saying that the people are the lynchpin of warehouse operations, construction, and management.

On one hand, it is true that technology might be advancing — top warehouses, with state-of-the-art set-ups rely on AI and automation for higher accuracy and productivity – but we are still in an age where warehouse managers continue to rely on human power and intelligence for their high rate of adaptability, critical thinking, problem-solving and operational cost-efficiency.

So, with people at the heart of this ecosystem, designing a warehouse that caters and uplifts their well-being has some significant benefits worth heeding.

What is Ergonomics in Warehousing?

There is no mincing words about the fact that warehouses are a high-risk work environment for people to be in. There is a constant risk of injury and fatality due to moving machinery and vehicles, exposed appliances and their proximity to people, heavy objects moving and falling, working at great heights and risk of people themselves falling.

In the past, warehouses were primarily built for storing inventory, so their design reflected this purpose. They were usually detail-deficient structures built to store surplus produce or passing cargo. These structures were often constructed out of wood, tin sheets or other light-weight material, which would be susceptible to fire, liable to natural elements and offer poor resistance against pestilence. They also had poor security and thus, prone to pilferage and thefts, and would generally be structurally weak in strength. In these warehouses, goods would be dumped to their brim with perhaps only this one nimble guy knowing where anything ever was.

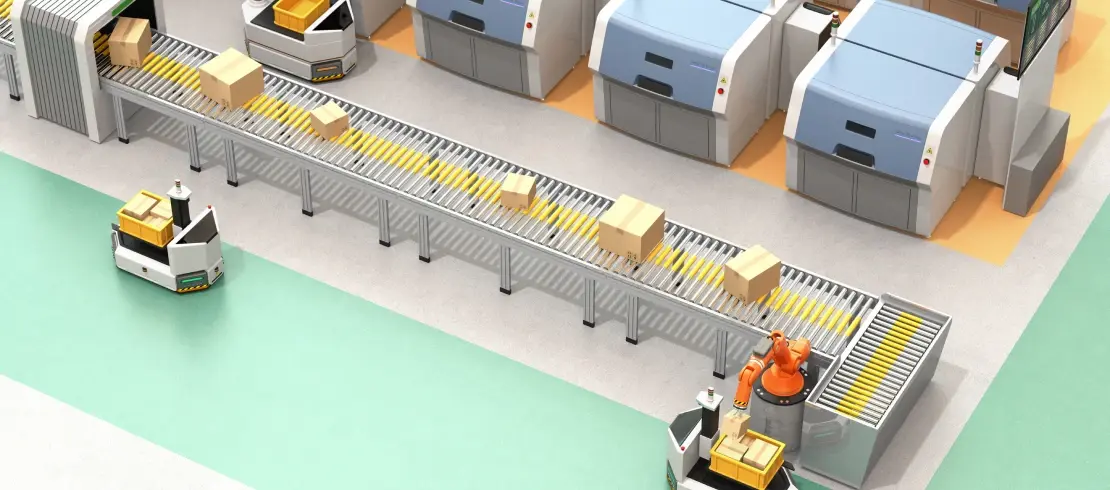

Comparatively, a modern ergonomic warehouse prioritises the well-being of people. It carefully considers how humans move within the space, how they occupy it, what equipment would be in use, and all the clearances these actions would require, to be executed safely without the goods obstructing their way (figure below). Additionally, they are better equipped with fire-resistant materials, sophisticated security systems, climate control, and advanced pest control methods. As a result, they have evolved to become one of the most critical components of global supply chains.

Designing An Ergonomic Warehouse

The layout of the warehouse vastly depends on the size and shape of the building, the access points possible, the type of equipment or machinery inside and the operations envisioned. Making the layout ergonomically compliant means ensuring that these details are considered while building and demarcating the functional areas. For example, a rectangular warehouse may have a straightforward layout and an efficient storage racking, but an irregular warehouse might need a little creativity to make the most of the space (figure below). Access points, including the loading docks, entrances, and exits, are especially located strategically to better facilitate the inflow and outflow of goods in a manner that minimises congestion and bottlenecks.

Different industries may require specific equipment or machinery for material handling and storage. An ergonomic warehouse design accommodates these needs by ensuring that there is adequate space and infrastructure to support the required equipment. All the functional areas are clearly demarcated.

Additionally, for the safety of the personnel, workspaces and walkways are designed for efficiency. This involves minimising walking distances across the floor, providing proper lighting and ventilation, ensuring clear sightlines, incorporating non-slip flooring and properly designed equipment to reduce the risk of accidents and injuries. To further reduce the risk of fatigue for the workers, the placement of storage racks, conveyor systems, and picking stations can also be tactfully planned to reduce travel time and effort for workers. For tasks beyond human capabilities, material handling equipment like forklifts or conveyor systems can be integrated into the warehouse for added optimisation.

Regular training and educating sessions can further facilitate in raising awareness and educate the workers about proper work techniques and safety protocols. Such initiatives also go a long way in maintaining a safe and efficient work environment.

Ergonomic Design and Cost Efficiency

An injury is not the only price to pay for a non-ergonomic warehouse design.

Poor ergonomics can be frustrating to work with and can directly impact the output quality of the workers.Improperly designed workstations or equipment can result in poor circulation within the warehouse premises resulting in longer travel times and unnecessary bottlenecks. For the workers, the extra effort may induce posture troubles, muscle stress, and fatigue. On a daily basis, fatigue and strain is likely to make them cause more mistakes or take longer periods to complete their tasks, affecting the efficiency of operations. Workers may require frequent breaks to relieve mental and physical strains. These breaks can quickly add up and have an impact on both timelines as well as on costs.

In the long term, the consequences of poor ergonomics can result in more employees having to take a higher number of time-offs to recover. Workers constantly subjected to straining postures or repetitive motions for longer periods are at risk of developing MSDs (musculoskeletal disorders) such as carpal tunnel syndrome, tendonitis, and back injuries. These add on to costs via the increased number of medical claims for such injuries and mishaps.

Another risk is a low-employee retention rate. Workers, especially skilled workers who care about their working situations are less likely to stick around for long term if they feel their organisation does not care about their safety. Replacing workers and training new ones has an impact on the productivity, efficiency, and operation cost.

What is the Solution?

Grade A warehouses are designed to tackle the challenges raised by poor ergonomics to better suit global working standards. These measures not just aim to improve human well-being and safety but also vastly improve the operational efficiency of their premises.

Design Intervention

Grade A warehouses employ strategic storage solutions where the placement is optimum. It minimises unnecessary bending, reaching and stretching for the workers. This not only minimises risk of MSDs but also makes use of the available storage space optimally and efficiently.

In emphasising on an efficient layout plan, Grade A warehouses enable streamlined circulation of inventory, people and machines. A good plan minimises scope for bottlenecks, unnecessary movements, and helps maintain clear pathways (figure below). This adds on to the reduction of human fatigue and achieving operational productivity and efficiency.

Awareness and Training

Well trained employees are more likely to follow protocols for efficiency and safety. Grade A warehouses understand this and hence, have regular learning and training sessions to keep all personnel informed and updated about practices, procedures, and protocols. This initiative goes a long way in minimising hazardous situations, injuries, and other health risks.

Leveraging Technology

In addition to all the above, Grade A warehouses can be built-to-suit to incorporate all kinds of latest automation and robotics. These technologies facilitate automation of repetitive tasks or help with the moving and lifting of heavy items safely. They help with the safety and efficiency, but also improve accuracy of operations greatly.

Regular Assessments

Finally, in Grade A warehouses, regular assessments about ergonomic compliance are a norm. These assessments help to spot any emerging ergonomic issues and allow one to take preventative action and make timely adjustments to workstations, equipment, processes and more. By staying proactive in this manner, these warehouses maintain a high standard as well as ensure worker well-being.